Vinayaga Cold Roll Sections

| Product | Profile Image | Applications |

|---|---|---|

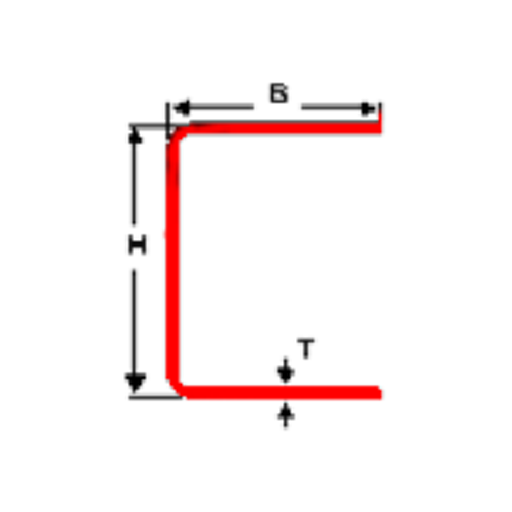

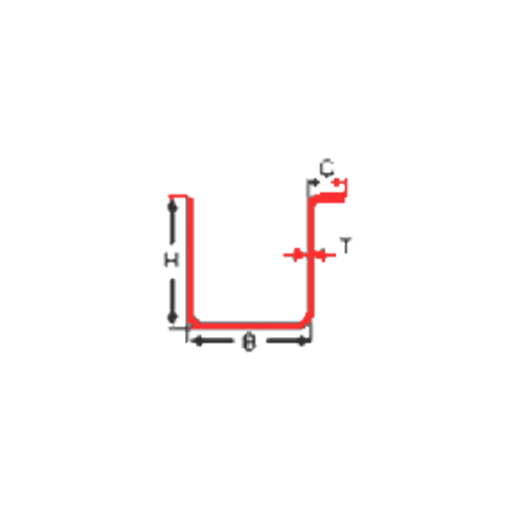

| Light Duty Channel |  |

In Scaffolding, Domestic appliances, Storage equipment, Racks and Storage System |

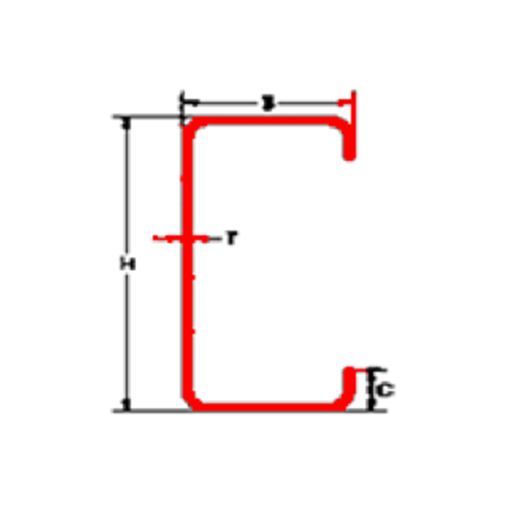

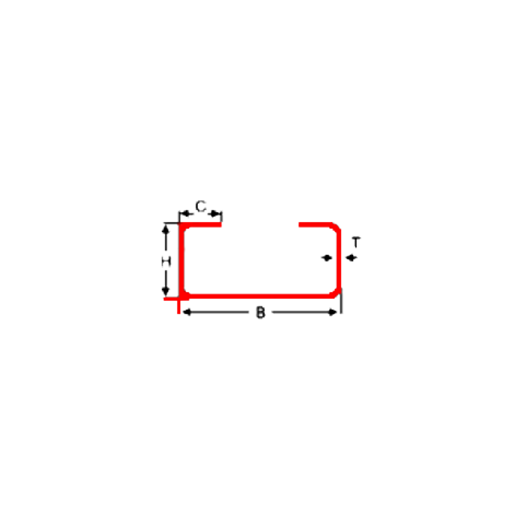

| C Purlin |  |

Architectural, structural buildings. Equipment frame Elevators and conveyors |

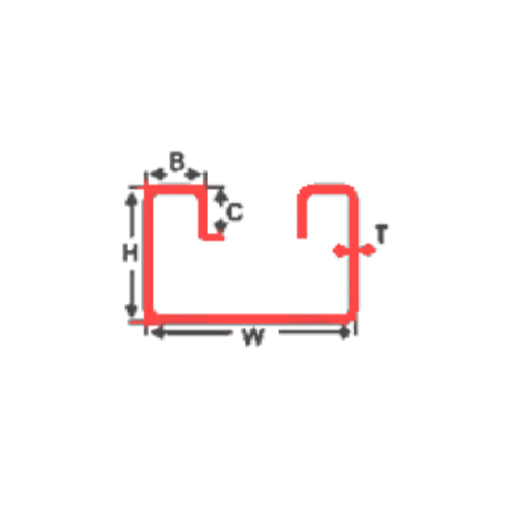

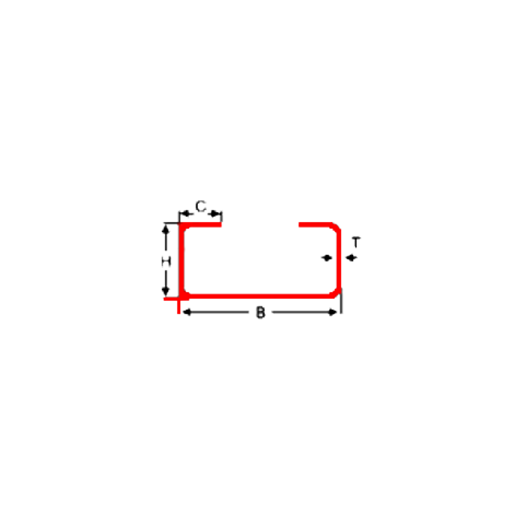

| Double Lip Channel |  |

Portable structures, Cabins & containers, for guardrail Machine base Racks and storage systems Over head trolley tracks for assembly lines |

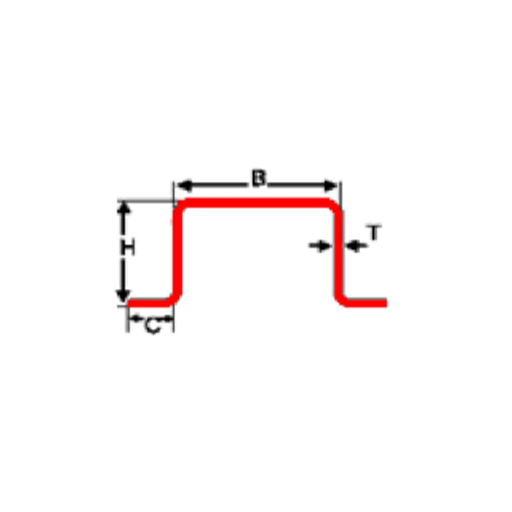

| Hat Section |  |

Truss member Automobile Body Fencing |

| One Side Lip Channel |  |

Rail Bogie Coaches Section |

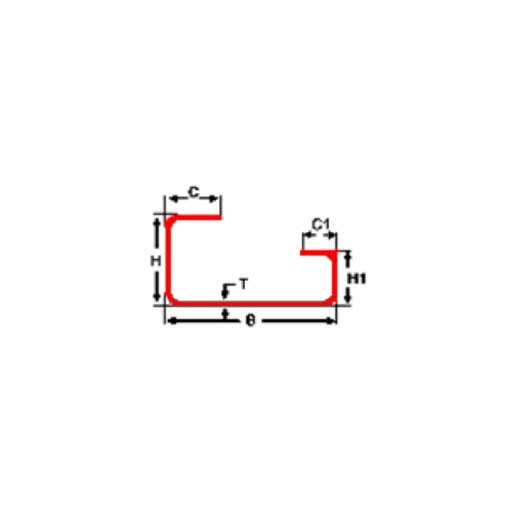

| U Lip Channel |  |

In high speed overhead conveyor system In automotive assembly shop Over head trolleys Light structure Machine base |

| Heavy Duty Channel |  |

As box section for beams, columns and mobile crane booms. As I section for beams, columns, EOT Gantry Girder In foundation base frames for heavymachineriesAs straight chasis members for LCV's and MCV's tippers |

| Terminal Mounting Channel |  |

In Electrical Installation |

| Z purlin |  |

Roof framing member allows flexural continuity between spans. Steel structure construction Industrial complex |

| Strut Section |  |

Storage System Steel Structure Conveyor Guides Automobile Industry Furniture |

| LAngle |  |

Transmission Towers Stiffeners Automobile Industry |

| Roller Door |  |

Conveyors in bottling industry Furniture |